Table of Contents

Regen a Freightliner

Since EPA’s emissions control technology regulations took effect on the production of diesel-powered engines, truck owners need to know how the process of regeneration works.

This article will explore the ways to identify when a regen is necessary, exactly how to regen a Freightliner, and additional information on after treatment systems.

STEP 1: Which Type of Regeneration Should You Perform?

So now that you know you need to perform regeneration, which type of regeneration should you perform?

-

i. Parked Regeneration: This is done when regeneration is needed immediately. Regeneration is needed immediately if one of your warning lamps indicates that as explained above.

-

ii. Passive Regeneration: Occurs all the time while the truck is driving at regular speeds. You don’t need to do anything special.

-

iii. Active Regeneration: Occurs while the truck is driving at high speeds.

We explain each process of how to regen a freightliner in the next section.

How To Regen A Freightliner With Different Types of Regeneration: Active, Passive, Parked

Here we’ll discuss the three types of regeneration that can be performed and go into the specific details of how to conduct a parked regen of a Freightliner truck with a Detroit diesel engine.

1. Parked Regeneration (Stationary Regeneration)

DPF Switch

If you’ve thoroughly read our above information on identifying warning lamps, then you should know when parked regeneration is needed and when you can do fine with the active option.

In other words, if your error codes indicate that regeneration is immediately needed, you may want to park your freightliner and conduct parked regeneration. Here is the process of proper parked regeneration:

Here’s how to regen a Freightliner using the parked/stationary procedure.

- Turn on the engine and slow idle for a few minutes. Make sure that it is not in the power-take-off mode

- Shift the transmission out of neutral and then back into neutral.

- Shift the parking brake from OFF to ON

- Press and release the clutch pedal

- Hold the DPF switch to the ON position for five continuous seconds then let go. At this point, the engine speed will ramp up (RPM increase), and the DPF warning lamp will disappear.

- The parked regen is now in process and should take 40 minutes to complete

- Make sure you do not push the key in the ignition to the off switch, depress the clutch, release parking brake, or put truck into gear. Any of these will stop the regeneration.

The regen has concluded when the engine returns to slow idle, and the DPF light remains out.

Remember, exhaust temperature increases during regeneration, so it is essential that this procedure is performed outside and away from flammable or combustible materials. Hopefully, you are now educated enough on how to perform a parked regeneration.

2. Active Regeneration

Active regeneration is the process of burning out the soot by raising the temperature from an outside energy source such as heated diesel fuel or the truck’s electricity.

How to do active regeneration? Well it only requires the driver to bring the vehicle up to highway speeds and no further action is needed. How does it work?

Well, simply, the sensors will detect that regeneration is needed and so fuel will be automatically injected to increase the temperature in your DPF.

This high temperature fuel injected then burns off accumulated soot. In some truck, this process may be done by an oxidizing catalytic converter that should also be checked and cleaned as needed.

It takes about 40-45 minutes of highway speed driving to complete an active regen.

3. Passive Regeneration

Passive regeneration occurs when the truck can maintain right exhaust temperatures so that the DPF can self-regenerate itself continuously.

This type of regeneration is continuously occurring as the driver goes about his business driving the truck as usual.

Passive regeneration is mainly featured in vocational trucks that are intended for off-road use such as logging or oilfield vehicles. No action is required from the operator for passive regen to occur.

How To Know When Your Freightliner Needs Regeneration?

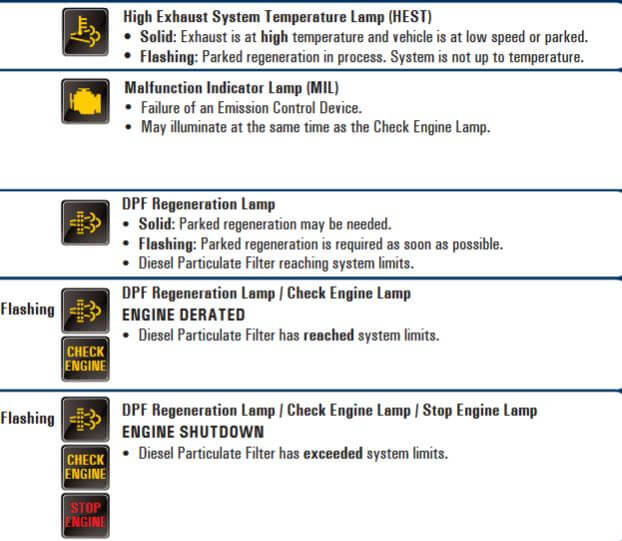

First Method: Error/Fault Code Lamps

The first step is to identify when a regeneration (regen) is needed. The primary way to get updates on the status of your diesel particulate filter and know when a regeneration is needed is to watch for error or warning lamps on your truck’s dash.

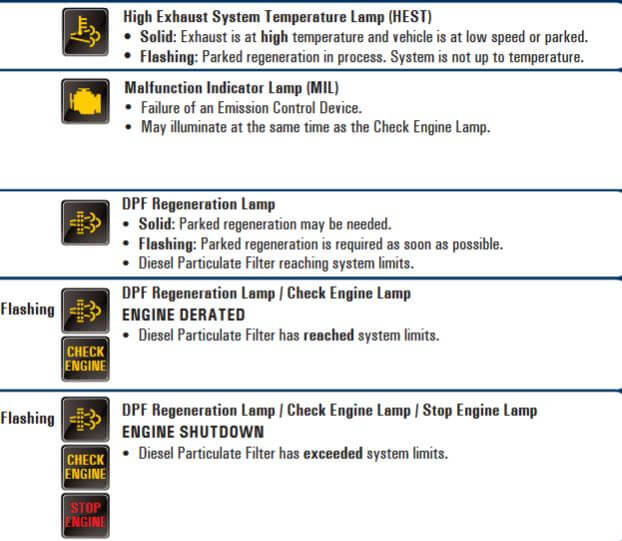

Fault Code Lamps before Freightliner regen

Lets look at these regen error codes:

i. The Malfunction Indicator Lamp/Check Engine

The malfunction indicator lamp is commonly called the check engine light.

This error lamp is based on an the engine-management system and usually indicates a malfunction somewhere in the engine.

Malfunction Indicator Lamp for regen

For a freightliner, many times the malfunction indicator lamp is a warning that part of the engine’s emission system is not working correctly.

Detroit Diesel has stated that the truck can be driven to the end of the shift and is not a warning indicator that requires immediate attention.

ii. The HEST Lamp

The HEST lamp is for high exhaust system temperature. It means that the exhaust is at high temperature due to extra regen speed which occurs when the truck is traveling at low rates or is parked.

The HEST Lamp rain

This warning light is merely to caution the operator to be careful around the hot exhaust system and to keep flammable materials or vapors at a safe distance.

iii. DPF Status Lamp

DPF lamp is the diesel particulate filter light and if it is stable then parked regeneration is required soon.

The DPF status light is very important to determine when DPF regeneration is needed for a Freightliner.

Now, in general, DPF warning lights might be solid or flashing. These two states indicate two different types of warnings:

DEF Lamp regen

If this light is flashing, then parked regeneration is needed immediately.

The other option here is to bring the vehicle to highways speed to enable an active regeneration of the filter.

Furthermore, if the DPF lamp illuminates alongside the check engine and stops engine light, then that means the diesel particulate filter has exceeded system limits, and your only option is to perform a parked regeneration.

If your truck is reaching its 500,000 miles or 10,000 hours mark, then it may even be time to replace the filter system altogether.

Second Method: Use A Scanner

An easy way to check if your DPF needs regeneration and check the general health of your Freightliner is to use use a scanner/code reader.

These heavy-duty scanners will tell the health of your DPF, oil and more. The NEXAS LUMNX-NL102P is a great example and a good option not only for freightliners, but cars and light-duty vehicles from 1996.You can use this device to fore regeneration for Detroit, Cummins, Maxxforce and more.

Third Method: The DPF Status Light Is On Steadily

The steady light is a warning that indicates that your engine may require regeneration. This also indicates that you may have a few or even several hours before the engine starts to de-rate.

In such a case, you can perform active or passive regeneration on the truck (these processes are explained below).

Basically, all you would have to do is to drive the at highway speeds (on a highway) uninterrupted. You can do so for about 45 minutes or so, but ensure the light goes away.

Forth Method: The DPF Status Light Is Flashing

Now a flashing light is more serious as it indicates that your DPF must be regenerated urgently.

This will happen especially if you have been ignoring the steady DPF status light. This light is telling you that parked regeneration is required and should be performed as soon as possible. Parked regeneration is explained below.

Fifth Method: DPF Light Flashing With Check Engine

Parked DPF regeneration must be performed immediately.

Warning: Remember, if the DPF isn’t cleaned for a long period of time, it will begin to derate. Even more serious, it will shut down at some point in time without any additional warning.

Aftertreatment Systems

If your truck has reached the 500,000 miles or 800,000-kilometer interval and a check engine light illuminates on your truck’s dashboard, then it may be telling you that manual ash must be removed from the DPF.

This means you or a mechanical technician needs to remove the DPF filter for manual cleaning.

Often you will need to replace the DPF filter entirely along with the diesel oxidation catalyst (DOC). This interval may occur sooner depending on your truck’s engine model/make/year.

Moreover, be informed of DPF filter cleaning methods and avoid the “bake & blow” procedure that blow compressed air into the DPF substrate to remove loose ash.

Sometimes thermal baking is used to burn off hydrocarbons clogging the filter. However, these methods are not correct cleaning methods and can damage an after-treatment system.

New Diesel Particulate Filter For Detroit Filter

In some cases, you may just want to change your DPF. Now if your Freightliner has a Detroit diesel engine, it’s pretty easy to get a replacement DPF. In fact, you can get one on Amazon!

The DD15 A6804910594 is a DPF for the 2007 2008 2009 Detroit Diesel DD15.

Conclusion

Smog can be caused by deleting your dpf

However, while the early technology for controlling emissions may not have been the most reliable, newer models have improved significantly regarding fuel efficiency and maintenance.

Look at the image below and see how countries such as China who have less strict pollution laws appear.

Do you want to wear face masks to breathe freely because air pollution levels are too high? Follow our advice and DO NOT DPF DELETE!

by

by