Table of Contents

Drive to Clean Exhaust System: What Is It?

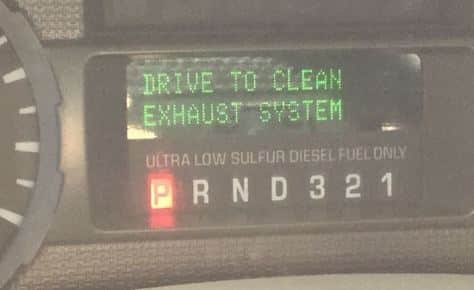

Drive to Clean Exhaust System or Drive to Clean Exhaust Filter is a message that will pop up on your dashboard, informing you that your DPF is blocked up and requires cleaning, as soon as possible.

Drive To Clean Exhaust System How Does It Work

For example, you may see this message when a Duramax required DPF cleaning.

On the other hand, some other brands such as Chevrolet may display something a little bit different, like “Cleaning Exhaust Filter Keep Driving.”

Why Do I Get The Drive to Clean Exhaust System Message?

With increasing EPA regulations, every diesel on the highway is required to be outfitted with a Diesel Particulate Filter or DPF.

The DPF is built inline to the exhaust pipe and burns soot from the engine into ash which is then trapped by a filter.

Why Do I Get The Drive to Clean Exhaust System Message

As more and more residue builds up in the filter, it must be cleaned. This cleaning process is called regeneration or regen for short.

Normally, DPF filter cleaning occurs automatically if the driver maintains sufficient speeds while driving on the highway.

In general, regeneration occurs at 100 to 500-mile intervals. However, there are many issues that may prevent regeneration and therefore cause the clean exhaust system message. Here are some of the issues that can prevent regeneration:

- Stop and go driving.

- Short driving distances.

- Turning the engine on and off by remote.

- Aftermarket air filters, air boxes, cold air kits, and exhaust add-ons.

What Should I Do When I Get The Drive To Clean Exhaust System Message?

As mentioned before, when you see this message on your dash, your DPF needs to be cleaned and you need to do so immediately.The process of cleaning the DPF is called regeneration.

What Should I Do When I Get The Drive To Clean Exhaust System Message

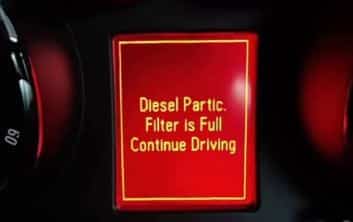

Now normally, the Drive to Clean Exhaust System or Drive to Clean Exhaust Filter message will appear and stay on the display for a few minutes and then it should change to something like Cleaning Exhaust Filter or DPF is Full Continue Driving which should stay on the display for the duration of the regeneration process.

DPF is full continue driving

Now there are different types of regeneration and the one you choose should depend on certain factors:

- If the Cleaning Exhaust Filter message appeasers quickly: Use Passive Regeneration

- If you have been doing a lot of round town driving: Use Active Regeneration

- If you have been driving short distances: Use Active Regeneration

- If you have been doing a lot of stop and go driving: Use Active Regeneration

- If the message appears while driving on the highway: Use Parked Regeneration

- If the Cleaning Exhaust Filter message does not appear after about 10 minutes after the Drive to Clean Exhaust System message: Use Parked Regeneration

Regeneration: Active, Passive and Parked Regeneration

As mentioned before, the type of regeneration that you use will depend on the factors mentioned above. Now let’s explain each type of regeneration:

Passive Regeneration

Passive regeneration or passive cleaning of a DPF filter utilizes normal exhaust temperatures and nitrous oxide as the catalyst.

This means that this mode of regeneration is automatic and straightforward and so the trapped soot is burned off as the vehicle operates.

In other words, DPF cleaning happens during normal driving.

When the warning messages appear, the driver can continue driving as normal if he/she intends to use passive regeneration.

DPF filter is full continue driving

Active Regeneration

Active Regeneration normally occurs during long haul or high speed driving, especially on the highway.

In this case, pressure sensors detect soot overload if normal driving patterns and passive regeneration have not adequately cleaned the DPF.

When the warning messages appears, it is prompting the driver to drive between say 17 to 30-mph speeds for roughly 20 minutes for active regeneration.

An engine control module informs the system to clean the filter using active regeneration. Exhaust temperatures are raised to dispose of pollutants.

During active regeneration, raw fuel is injected into the diesel oxidation catalyst (DOC) system to burn off soot and ash in the DPF.

Driver intervention is not needed for either of the above regeneration processes.

Parked or Operator Command Regeneration

If your diesel-equipped vehicle cannot maintain speed for passive or active regeneration, a driver must use parked or operator command regeneration.

This method allows an operator to initiate regeneration while the vehicle is parked or idle. The particulate filter must be at 100% load for the operator command to work.

Here are the steps to complete parked regeneration:

- Start the vehicle and bring it to operating temperature.

- Press the information display button and follow and understand the prompts.

- Answer yes to start the process and exhaust positioning.

- Once an operator regeneration has commenced, the engine will rev to 2000 rpm.

- Regeneration process ends, the engine and cooling fan will return to normal. The exhaust system will be hot. The complete regeneration takes about 30 minutes.

If you drive a Freightliner and need more details on how to conduct parked regeneration, please check out this guide open how to regen a freightliner.

While these methods of regeneration are different, they all follow the same basic principle. Diesel particulates burn off at 600 degrees Celsius and above.

Onboard active systems use extra fuel or extra power to the DPF’s electrical structure to complete this burn-off.

Regeneration is the process of eliminating built-up soot and ash from the DPF filter. Every diesel builder has different procedures or displays messages for this process.

However, the fundamental objective is the same. Each regeneration cycle will last between 9 to 20 minutes.

Other Important DPF Warning Messages

Modern warning system technology is nothing short of remarkable. Today’s digital vehicles are equipped with hundreds of sensors, communicating every conceivable condition, and making repairs easier.

A service technician can diagnose problems quicker, with greater certainty. Operators need to pay attention to any DPF messages:

- Exhaust Filter Overloaded, Drive to Clean

- Exhaust Filter at Limit Drive to Clean Now

Overlooking DPF warning message can lead to a trip to your dealer’s service department. An example message that may show if you ignore warnings is “Exhaust Filter Over Limit, Service Now”.

If the operator sees this message on their screen, there will be a 20% to 30% cutback in torque. Regeneration is disabled, and a certified technician must clean the filter.

Additional messages related to DPF cleaning:

- Exhaust Filter at Limit, Clean Now

- Exhaust System Overheated, Stop Now

- Exhaust Filter Drive Complete

Why Do We Get Emission Errors?

Diesel engine manufacturers have endeavored to produce engines that operate cleaner without generating an overabundance of toxins.

The results in significant internal combustion engines, yielding excellent fuel mileage, exceptional torque and is extremely reliable.

This type of engine design can be applied to a small two-door passenger automobile or gigantic earthmovers and beyond.

Why Do We Get Emission Errors

Engineers have worked continuously to improve diesel exhaust emissions. In the early days of diesel engines, soot, ash, nitrous oxide, and other harmful particulates billowed from their tailpipes.

In recent decades, two major emission technologies have come into play to help fix these issues:

- Diesel exhaust fluid (DEF) has negated detrimental effects of nitrous oxide

- Diesel particulate filters (DPF) curtail soot, ash and other carbon-based pollutants.

Drive To Clean Exhaust System is just one of the errors that help you to fix emissions issues yourself.

Diesel Particulate Filters and Diesel Exhaust Fuel

Two primary pollutant control systems exist on modern diesel engines. Diesel exhaust fuel (DEF) and Diesel particulate filters (DPF).

Under certain conditions, a DPF will remove 85% to 100% of the particulate matter coming from diesel exhaust. The filter must be maintained continually, or the DPF will not function correctly.

Diesel Particulate Filters and Diesel Exhaust Fuel

Diesel soot is generated from incomplete combustion of diesel fuel. Carbon and other particulates vary, depending on engine type, size, and fuel used. Particulate filters have been employed since the mid-1970s and used in vehicles since 1985.

Several filter technologies are in use today:

- Cordierite is the most common material. Ceramic-based cordierite has excellent filtering properties, inexpensive and thermally efficient.

- Silicon carbide is the second most common filtering material. The silicon carbide has a higher melting point, but not as thermally efficient.

DPF filters have developed into the most economical means to capture and dispose of diesel particulate matter.

Regeneration techniques have been able to prolong the life of filters, by “burning off” soot and other carbon particles.

Thermal regeneration is by far the most complete and efficient form of operating particulate filters.

Key Takeaways

The continued progression of DPF and DEF systems are growing pains for emission regulations. In the 60s, there were no automotive standards to control what was coming out of the tailpipe.

Americans could see the impact of dirty diesel fuel, from the billows of black smoke gushing out of exhaust pipes.

Current EPA regulations, which took effect in 2010 have reversed the trend. Modern diesel engines run much cleaner and operate at higher efficiencies.

The 2010 EPA regulations for diesel engines was by far the most significant clean-air regulation in our lifetime. It is believed, the standards will reduce carbon and nitrous oxide emissions by 1 million tons per year.

It is equivalent to removing 35 million passenger cars from the highway. The drive to clean exhaust system is one of those important controls that is helping us to get the job done.

by

by